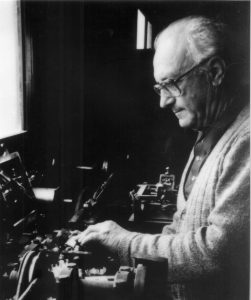

60 years of passion in making reeds

The cane is cut during winter (From December to march) and is stocked on trestles in an upright position until May, hile the initial drying process takes place, and while the sap contained in the cane slowly descends by means of capillarity. The cane is then stripped of its leaves and branches, and cut at a height 6.5-8 feet, only the lower portion being used for the manufacture of reeds. The selected tubes are laid out side by side to dry, being turned at regular interval so that the sun can bronze them and harden the varnish evenly around the circumference. This also enables the cane to develop a sustained yellow color, something which is difficult to achieve with cane from regions other than the Var region. The frying time varies according to the amount of the sun that the cane receives. The tubes are then restocked in a well-aired place. After a certain time while the cane rests and stabilizes itself, it is then selected for use in production of the reeds. The amount of cane to be stocked needs to be carefully planned out, so as to assure enough for one year’s production. Marca use 200.000 Canes by year for his production of reed. It is at this timethat still raw cane progressively begins its transformation process into Marca Reeds.

PREPARATION OF THE CANE

The cane is cut during winter (From December to march) and is stocked on trestles in an upright position until May, hile the initial drying process takes place, and while the sap contained in the cane slowly descends by means of capillarity. The cane is then stripped of its leaves and branches, and cut at a height 6.5-8 feet, only the lower portion being used for the manufacture of reeds. The selected tubes are laid out side by side to dry, being turned at regular interval so that the sun can bronze them and harden the varnish evenly around the circumference. This also enables the cane to develop a sustained yellow color, something which is difficult to achieve with cane from regions other than the Var region. The frying time varies according to the amount of the sun that the cane receives. The tubes are then restocked in a well-aired place. After a certain time while the cane rests and stabilizes itself, it is then selected for use in production of the reeds. The amount of cane to be stocked needs to be carefully planned out, so as to assure enough for one year’s production. Marca use 200.000 Canes by year for his production of reed. It is at this timethat still raw cane progressively begins its transformation process into Marca Reeds.

MARCA CANE FROM PROVENCE

The cane industry began to develop with the arrival of many basket makers, maintly Italian, who came to work in the basket industry. Ollioules found itself to be the center of this workforce, who were employed by one of their compatriots. As this material was more and more exploited along the Mediterranean coast, these workers gradually set themselves up as artisans in the areas around Nice, Antibes, Cannes Hyéres and Ollioules. To supply themselves with the raw material needed to weave their baskets, they would harvest the cane which surrounded them. Once the demand for cane for musical instruments began to grow, it was natural for them to involve themselves to the competences required for this new task. As regards my own family, we have been working on cane and on reeds for five generations.

HIGH QUALITY MADE SINCE 1957